Dosing pumps are a vital tool in various industries that require precise and efficient chemical dispensing. These pumps offer numerous benefits, making them an essential component of many processes.

Firstly, dosing pumps ensure accuracy

With their ability to deliver consistent and precise amounts of chemicals, they eliminate the risk of under or over-dosing. This accuracy not only improves the quality of products but also minimizes waste and reduces costs.

Secondly, dosing pumps enhance efficiency.

By automating the dispensing process, they save time and manpower while maintaining a high level of precision. Operators can rely on these pumps to deliver chemicals at predetermined rates continuously, allowing for optimized workflow and increased productivity.

Lastly, these pumps offer versatility.

They can handle a wide range of chemicals with varying viscosities and corrosive properties. Whether it’s handling acids, alkalis, polymers, or other substances, dosing pumps provide reliable performance across diverse applications.

In conclusion, investing in These brings numerous advantages to businesses reliant on accurate chemical dispensing. From improved accuracy to enhanced efficiency and versatile functionality, these pumps play a crucial role in optimizing processes and achieving optimal results in various industries.

Chemical dosing pumps are essential tools used in various industries to accurately and precisely deliver chemicals or other substances into a process. These pumps ensure the controlled dosage of chemicals, which is crucial for maintaining efficiency, safety, and productivity.

There are several types of chemical dosing pumps available on the market today. Let’s explore some common ones:

- Diaphragm Pumps: Diaphragm pumps feature a flexible diaphragm that moves back and forth to displace the liquid. They are known for their self-priming ability and can handle abrasive or viscous fluids without any damage to the pump itself.

- Peristaltic Pumps: Peristaltic pumps use rotating rollers or shoes to compress a tube containing the chemical solution, forcing it through while preventing backflow. This design makes them suitable for handling corrosive liquids or those with high solid content since they have no direct contact with moving parts.

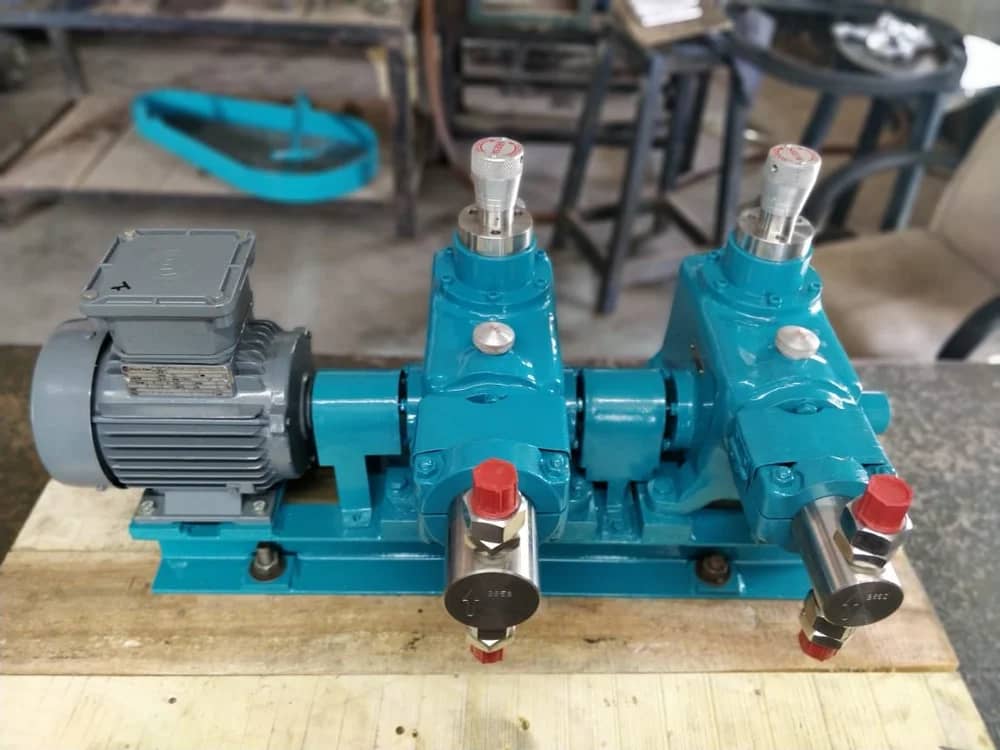

- Piston Pumps: Piston pumps work by reciprocating pistons driven by an electric motor or air pressure. They can generate high pressures and handle low flow rates accurately, making them ideal for precise dosing applications.

- Solenoid Dosing Pumps: Solenoid-driven dosing pumps utilize an electromagnetic solenoid coil to drive a plunger or valve mechanism that controls the flow rate of chemicals being dispensed. These compact and cost-effective pumps are commonly used in smaller-scale applications where accurate dosing is required.

- Motor-Driven Dosing Pumps: Motor-driven dosing pumps operate using an electric motor coupled directly to a piston or diaphragm assembly, allowing for precise control over flow rates and pressures. They offer flexibility in terms of speed adjustment and can be easily integrated into automated systems.

- Progressive Cavity (PC) Pumps: PC pumps consist of a helical rotor inside a stator, creating cavities that move fluid from the suction to the discharge side. These pumps are capable of handling high-viscosity fluids and maintaining a consistent flow rate, making them suitable for applications where dosing accuracy is critical.

When selecting a chemical dosing pump, factors such as required flow rate, pressure range, compatibility with chemicals being used, maintenance requirements, and cost should be considered. Consulting with experts or suppliers in the field can help determine the most appropriate type of pump for your specific application.

When it comes to the price of dosing pumps, several factors can influence the overall cost. These factors include the type and size of the pump, its material construction, brand reputation, additional features or accessories, and where you purchase it from.

- Type and Size: Different types of dosing pumps have varying price ranges. Generally, simpler pumps like solenoid-driven or peristaltic pumps tend to be more affordable compared to motor-driven or piston pumps. Additionally, larger capacity pumps will typically cost more than smaller ones due to their higher flow rates and increased materials required for construction.

- Material Construction: The materials used in manufacturing a dosing pump can impact its price. Pumps constructed with corrosion-resistant materials such as stainless steel or specialized plastics may come at a higher cost but offer durability and longevity in harsh chemical environments.

- Brand Reputation: Well-established brands that are known for producing high-quality dosing pumps often command higher prices due to their reputation for reliability and performance. While opting for reputable brands might increase upfront costs, it can provide long-term benefits by minimizing maintenance requirements and ensuring consistent operation.

- Additional Features/Accessories: Some dosing pumps may come with additional features like digital controls, flow rate adjustment mechanisms, integrated timers or controllers, remote monitoring capabilities, etc., which add functionality but also increase the overall price.

- Supplier/Source: Prices can vary depending on where you purchase your dosing pump from – directly from manufacturers, authorized distributors/dealerships, or online marketplaces. It’s recommended to compare prices from different sources while considering factors such as warranty support and after-sales service.

It is important to note that specific pricing information cannot be provided here as it is subject to change over time and based on individual suppliers’ policies. To get accurate pricing details for a particular dosing pump model or brand that suits your requirements best, reaching out to suppliers directly or checking their websites would be the most reliable approach.